In Phoenix, the harsh desert heat can be tough on floors, making epoxy and polyaspartic coatings essential for protecting your garage or commercial space. Here’s a breakdown of common terms to help you navigate the world of the epoxy flooring industry.

Garage Floor Coating

In Phoenix, “garage floor coating” refers to the use of epoxy or polyaspartic coatings to protect concrete floors from chemical spills, abrasions, and heavy loads. These coatings are perfect for garages, where they provide a sleek, durable finish that can handle daily wear and tear.

Concrete Paint

Though some people call these coatings “concrete paint,” epoxy and polyaspartic are far more durable. True concrete paint doesn’t bond to the concrete like epoxy does, meaning it’s more likely to peel or crack, especially in Phoenix’s hot climate. Epoxy is the better option for long-term durability.

Epoxy Coating

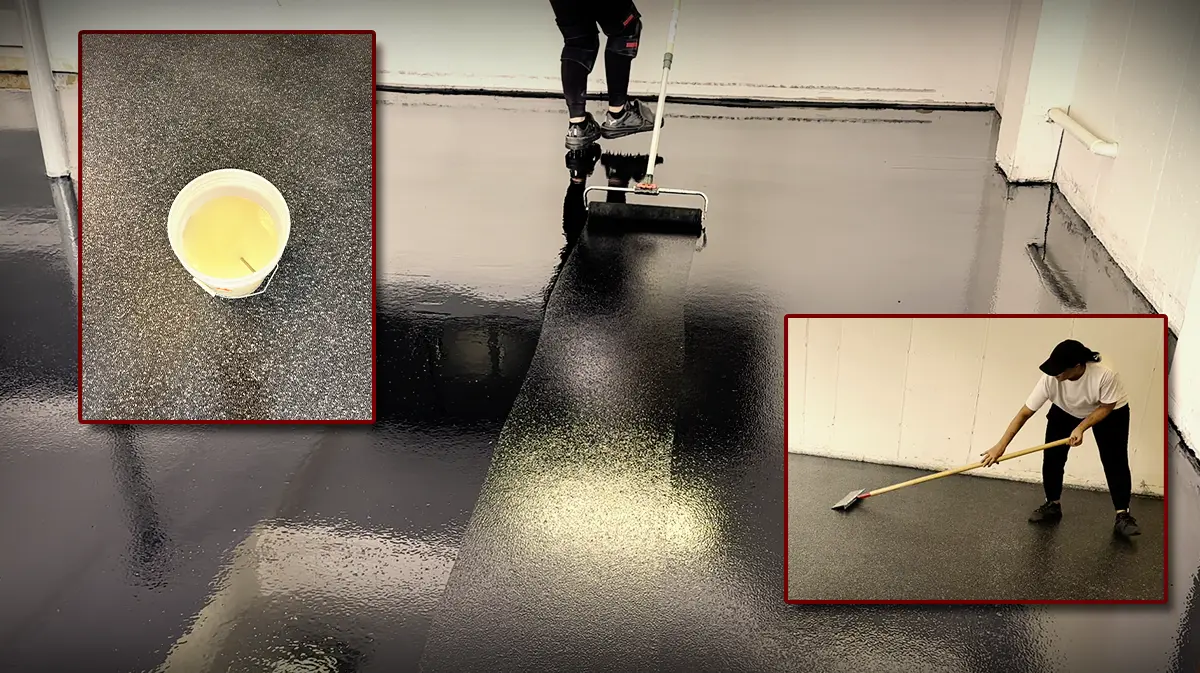

An epoxy coating is a durable solution that bonds with concrete to create a long-lasting, protective surface. In Phoenix, epoxy coatings are perfect for garages and commercial spaces, offering resistance to heat, oil spills, and heavy traffic. The protective layer is strong enough to handle everything the desert climate throws at it.

Polyaspartic Coating

Polyaspartic coatings cure much faster than epoxy and are UV-resistant, making them perfect as topcoats for garages and outdoor areas exposed to the Phoenix sun (they’re poor direct-to-concrete primer coats, however). They offer high durability and won’t yellow over time (conversely, an epoxy will yellow if exposed to UV, so they’re best used as primer coats under these conditions). Plus, polyaspartic coatings can be walked on in just hours, making them ideal for busy homes and businesses that need quick turnarounds.

Polyurethane

Another option for a clear top coat (usually applied over an epoxy primer coat) is a polyurethane. The coatings strongly resist UV rays, scratches, and chemical spills. In Phoenix, where sun exposure can be intense, polyurethane helps keep your floors looking fresh and new for years to come. However, these coatings do not resist hot tire transfer (plasticizer migration) and so are not to be used in garages as a top coat. They are best used as top coats for patios, walkways, etc., where no vehicular traffic is present.

Flake Epoxy Floor System

A flake epoxy floor system adds both visual appeal and slip resistance. In Phoenix, where garages and outdoor spaces can get wet from rain or pool water, this system helps prevent slips while giving your floor a unique, textured look.

Mica Flakes

For a more luxurious finish, mica flakes are a great choice. These natural minerals give your floor a highly reflective sheen, making it stand out. In Phoenix, they’re often used in high-end garages or commercial spaces to add a touch of sophistication.

Moisture Mitigation

Even in the desert, moisture mitigation is important. Using a moisture-mitigating epoxy as the direct-to-concrete primer coat ensures deep penetration and proper bonding to the concrete substrate. In our flooring, quick curing polyureas or polyaspartics are used as clear topcoats only…never as primer coats. This approach prevents future peeling or bubbling due to moisture-related issues (e.g., moisture vapor transmission and high hydrostatic pressure). This is especially important for areas like basements or garages that might be exposed to continuous or occasional moisture infiltration.

Conclusion

In Phoenix, epoxy coatings offer the durability needed to withstand the heat while keeping your floors looking polished. Whether you’re coating your garage or a commercial space, understanding these terms of the epoxy flooring industry will help you choose the right option for durable, long-lasting floors.